Case 445 Service Manual

Posted : admin On 02.01.2020. REPAIR MANUAL TOOLS AND COUPLERS 445CT 39753 1. Contents TOOLS AND COUPLERS - J CARRYING Unarticulated tools J.50.B 435, 445CT, 445 COUPLING Hydraulic coupling J.80.C 435, 445CT, 445 COUPLING Mechanical coupling J.80.B 435, 445CT, 445 39753 1. TOOLS AND COUPLERS - J CARRYING Unarticulated tools - 50.B 445CT 39767 1 J.50.B / 1.

TOOLS AND COUPLERS - J CARRYING Unarticulated tools - 50.B TECHNICAL DATA Tool Tool Bucket - General specification (J.50.B.60.62 - D.40.A.10) 435, 445, 445CT SERVICE Tool Tool Cutting edge - Replace (J.50.B.60.64 - F.10.A.30) 435, 445, 445CT 39767 1. TOOLS AND COUPLERS - CARRYING Unarticulated tools Tool Bucket - General specification (J.50.B.60.62 - D.40.A.10) 435, 445, 445CT BT97G325 1. 10 mm (3/8 in) fillet (weld twice 1 root pass 1 cover 3. 6 mm (1/4 in) groove 6 mm (1/4 in) fillet (weld.

TOOLS AND COUPLERS - CARRYING Unarticulated tools Tool Cutting edge - Replace (J.50.B.60.64 - F.10.A.30) 435, 445, 445CT To replace welded cutting edges, raise the bucket to an acceptable height and place supports to hold the bucket in position. Use carbon arc rod or an acetylene torch to remove the welds that hold the cutting edge. Index TOOLS AND COUPLERS - J CARRYING Unarticulated tools - 50.B Tool Bucket - General specification (J.50.B.60.62 - D.40.A.10) 435, 445, 445CT Tool Cutting edge - Replace (J.50.B.60.64 - F.10.A.30) 435, 445, 445CT 39767 1 J.50.B / 5.

39767 1 J.50.B / 6. TOOLS AND COUPLERS - J COUPLING Hydraulic coupling - 80.C 445CT 39769 1 J.80.C / 1. TOOLS AND COUPLERS - J COUPLING Hydraulic coupling - 80.C SERVICE Command valve Command valve Solenoid - Remove (J.80.C.12.05 - F.10.A.10) 435, 445, 445CT Command valve Solenoid - Install (J.80.C.12.05 - F.10.A.15) 435, 445, 445CT Control valve Control valve - Remove (J.80.C.13 - F.10.A.10) 435, 445, 445CT Control valve - Install (J.80.C.13 - F.10.A.15).

TOOLS AND COUPLERS - COUPLING Hydraulic coupling Command valve Solenoid - Remove (J.80.C.12.05 - F.10.A.10) 435, 445, 445CT Loosen and remove the mounting bolts (4) from the upper step plate (6 ). Remove the step plate (6) from the loader frame. TOOLS AND COUPLERS - COUPLING Hydraulic coupling bs04d016 Hydraulic Coupler Solenoid Valve 1. Solenoid valve 3.

Hydraulic hose connections 2. Wire harness 4. Valve mounting bolts 1 J.80.C / 4. TOOLS AND COUPLERS - COUPLING Hydraulic coupling Command valve Solenoid - Install (J.80.C.12.05 - F.10.A.15) 435, 445, 445CT Install the Solenoid Valve (1) onto the step plate (6) mounting location. Install the mounting bolts (5) into the Solenoid Valve (1) and tighten the mounting bolts (5).

TOOLS AND COUPLERS - COUPLING Hydraulic coupling Check the oil level in the reservoir and add hydraulic oil as required. Reservoir - Filling (A.10.A.22 - F.60.A.10) 1 J.80.C / 6. TOOLS AND COUPLERS - COUPLING Hydraulic coupling Control valve - Remove (J.80.C.13 - F.10.A.10) 435, 445, 445CT For loader control valve removal refer to the following procedure. Control valve - Remove (H.40.B.13 - F.10.A.10) 1 J.80.C / 7. TOOLS AND COUPLERS - COUPLING Hydraulic coupling Control valve - Install (J.80.C.13 - F.10.A.15) 435, 445, 445CT For loader control valve installation refer to the following procedure. Control valve - Install (H.40.B.13 - F.10.A.15) 1 J.80.C / 8.

TOOLS AND COUPLERS - COUPLING Hydraulic coupling Mechanical connector - Disassemble (J.80.C.66 - F.10.A.25) 435, 445, 445CT Loosen and remove the hydraulic hoses from the cylinders (6). Plug the hoses and cap the fittings on the cylinders (6). Loosen and remove the nut (5), bolt (3), 2 washers (4) and spacer (15) from the left and the right lower pins (14) of the coupler frame (1).

TOOLS AND COUPLERS - COUPLING Hydraulic coupling bs04d225 Exploded View of Hydraulic Attachment Coupler 1. Coupler frame 6.

Lube fitting 16. Right side indicator 2. Protective plate 7. Clevis pin 12. Hook wedge 17. Left side indicator 3.

Service Manual Free Download

TOOLS AND COUPLERS - COUPLING Hydraulic coupling bs04d014 Attachment Coupler Hydraulic Installation 7. Coupler frame 4. Coupler cylinders 5. Double check valve 3.

Solenoid valve 1 J.80.C / 11. TOOLS AND COUPLERS - COUPLING Hydraulic coupling Mechanical connector - Assemble (J.80.C.66 - F.10.A.20) 435, 445, 445CT Install the hook wedge (12) onto the bottom of the cylinder (6). Install the clevis pin (7) through the hook wedge (12). Install the washer (4) onto the clevis pin (7). TOOLS AND COUPLERS - COUPLING Hydraulic coupling bs04d225 Exploded View of Hydraulic Attachment Coupler 1.

Coupler frame 6. Lube fitting 16. Right side indicator 2. Protective plate 7.

Clevis pin 12. Hook wedge 17. Left side indicator 3. TOOLS AND COUPLERS - COUPLING Hydraulic coupling bs04d014 1. Coupler frame 4. Coupler cylinders 5.

Double check valve 3. Solenoid valve 1 J.80.C / 14. TOOLS AND COUPLERS - COUPLING Hydraulic coupling Mechanical connector - Visual inspection (J.80.C.66 - F.40.A.10) 435, 445, 445CT Inspect the coupler frame (1) to be sure it is free of cracks, corrosion, rust or any other damage. Use new parts as required. TOOLS AND COUPLERS - COUPLING Hydraulic coupling bs04d225 Exploded View of Hydraulic Attachment Coupler 1. Coupler frame 6. Lube fitting 16.

Right side indicator 2. Protective plate 7. Clevis pin 12. Hook wedge 17. Left side indicator 3. TOOLS AND COUPLERS - COUPLING Hydraulic coupling Non-return valve - Remove (J.80.C.17 - F.10.A.10) 435, 445, 445CT Loosen and remove the mounting bolts from the lower step plate (not shown).

Remove the step plate from the Coupler frame. Bs04d0151 Hydraulic Coupler Double Check Valve Installation 1. TOOLS AND COUPLERS - COUPLING Hydraulic coupling Non-return valve - Install (J.80.C.17 - F.10.A.15) 435, 445, 445CT Install the Double Check Valve (1) in the Coupler frame mounting location.

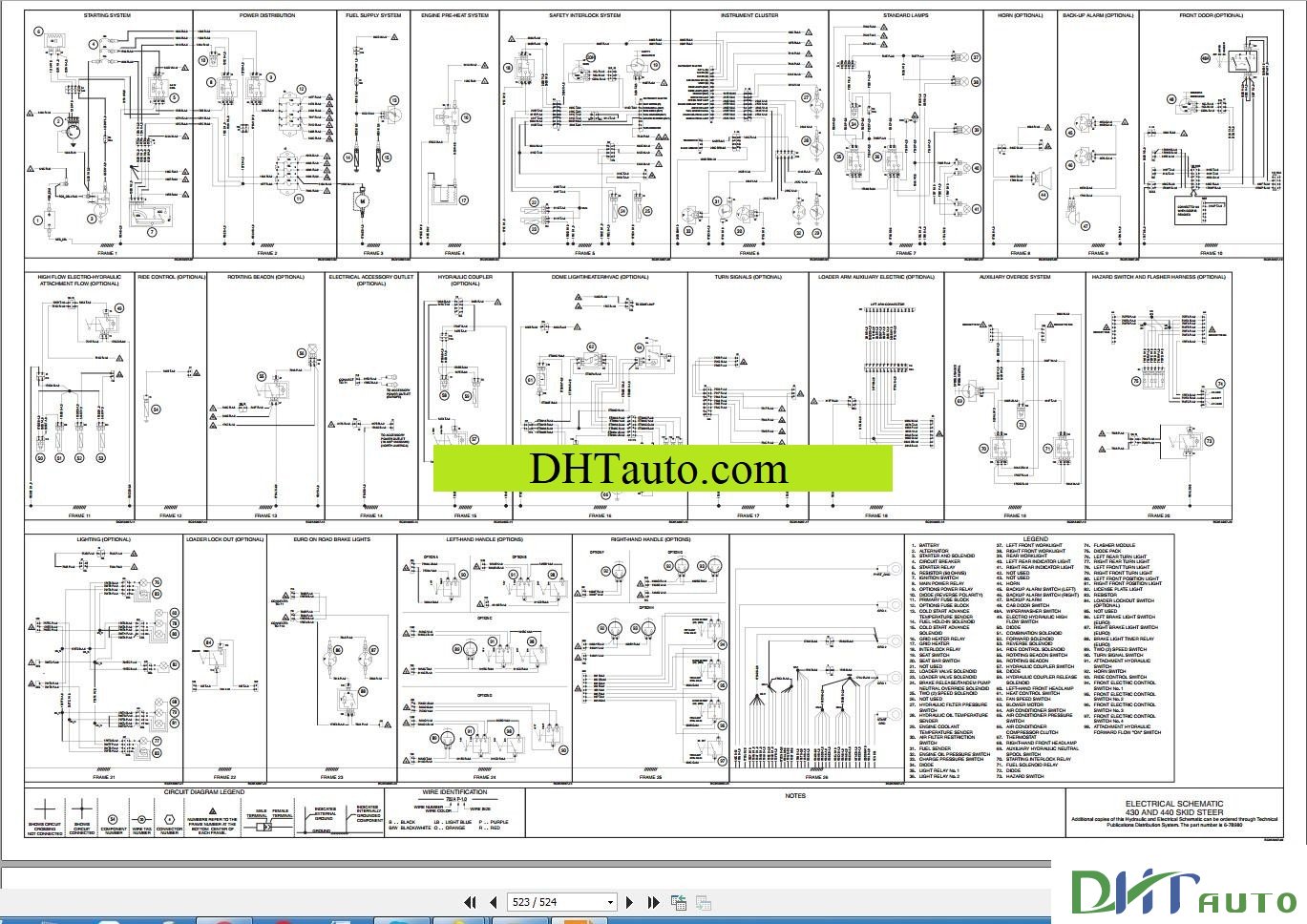

Install the mounting bolts (5) into the Double Check Valve (1). Tighten the mounting bolts (5). TOOLS AND COUPLERS - COUPLING Hydraulic coupling Command valve Solenoid - Testing (J.80.C.12.05 - G.40.A.20) 435, 445, 445CT NOTE: For wiring diagram refer to Wiring harness - Electrical schematic frame 15 (A.30.A.88 - C.20.E.15) N° Test Point Expected Result Other Result (Possible Cause) 1 Terminal for wire 178 to ground. TOOLS AND COUPLERS - COUPLING Hydraulic coupling Electrical control Coupler switch - Testing (J.80.C.90.81 - G.40.A.20) 435, 445, 445CT NOTE: For wiring diagram refer to Wiring harness - Electrical schematic frame 15 (A.30.A.88 - C.20.E.15) N° Test Point Expected Result. TOOLS AND COUPLERS - J COUPLING Hydraulic coupling - 80.C Command valve Solenoid - Install (J.80.C.12.05 - F.10.A.15) 435, 445, 445CT Command valve Solenoid - Remove (J.80.C.12.05 - F.10.A.10) 435, 445, 445CT Command valve Solenoid - Testing (J.80.C.12.05 - G.40.A.20) 435, 445, 445CT Control valve - Install (J.80.C.13 - F.10.A.15). 39769 1 J.80.C / 22. TOOLS AND COUPLERS - J COUPLING Mechanical coupling - 80.B 445CT 39770 1 J.80.B / 1.

TOOLS AND COUPLERS - J COUPLING Mechanical coupling - 80.B SERVICE Connector Connector - Disassemble (J.80.B.66 - F.10.A.25) 435, 445, 445CT Connector - Assemble (J.80.B.66 - F.10.A.20) 435, 445, 445CT Connector - Visual inspection (J.80.B.66 - F.40.A.10) 435, 445, 445CT 39770 1 J.80.B / 2. TOOLS AND COUPLERS - COUPLING Mechanical coupling Connector - Disassemble (J.80.B.66 - F.10.A.25) 435, 445, 445CT Loosen and remove the nut (20), bolt (17), two washers (19) and spacer from the left and right lower pins of the coupler frame (1). TOOLS AND COUPLERS - COUPLING Mechanical coupling BT97H016 Exploded View of Mechanical Attachment Coupler 1. Coupler frame 8. Left handle 9. Spring guide 16.

Right handle 10. Compression spring 17. Lube fitting 11. TOOLS AND COUPLERS - COUPLING Mechanical coupling Connector - Assemble (J.80.B.66 - F.10.A.20) 435, 445, 445CT Place the left handle (2) in a vise with soft jaws. Install the trunnion (8) into the left handle (2). Install the link rod (13) through the spring (10) and the spring guide (8). TOOLS AND COUPLERS - COUPLING Mechanical coupling BT97H016 Exploded View of Mechanical Attachment Coupler 1.

Coupler frame 8. Left handle 9. Spring guide 16.

Right handle 10. Compression spring 17. Lube fitting 11. TOOLS AND COUPLERS - COUPLING Mechanical coupling Connector - Visual inspection (J.80.B.66 - F.40.A.10) 435, 445, 445CT Inspect the coupler frame (1) to be sure it is free of cracks, corrosion, rust or any other damage. Use new parts as required. TOOLS AND COUPLERS - COUPLING Mechanical coupling BT97H016 Exploded View of Mechanical Attachment Coupler 1. Coupler frame 8.

Left handle 9. Spring guide 16. Right handle 10. Compression spring 17.

Lube fitting 11. Index TOOLS AND COUPLERS - J COUPLING Mechanical coupling - 80.B Connector - Assemble (J.80.B.66 - F.10.A.20) 435, 445, 445CT Connector - Disassemble (J.80.B.66 - F.10.A.25) 435, 445, 445CT Connector - Visual inspection (J.80.B.66 - F.40.A.10) 435, 445, 445CT 39770 1. All rights reserved. No part of the text or illustrations of this publication may be reproduced. Case Corporation reserves the right to make improvements in design or changes in specifications at any time without incurring any obligation to install them on units previously sold. All rights reserved. No part of the text or illustrations of this publication may be reproduced.

Case Corporation reserves the right to make improvements in design or changes in specifications at any time without incurring any obligation to install them on units previously sold.

Case 446 Service Manual

Clear, printable PDF Instant download Covers: Case New Holland 445/M2, 445T/M2, 668T/M2 Tier II Engine Pages: 180 Format: PDF Compatibility: Windows/Mac computers File size: 65mb Notes: Please contact us if you have compatibility questions This service manual contains the necessary technical information to carry out repair and overhaul on CNH 445/M2, 445T/M2, 668T/M2 Tier II engines, necessary tools to carry out those operations and information on service standard, on procedures for connection, disconnection and disassembly and assembly of parts.