Mercury Trim Tilt Manual

Posted : admin On 20.01.2020Tilt and Trim Motor Replacing Power Trim and Tilt Systems When replacing your Power Tilt and Trim Motor, first identify what type of Power Tilt and Trim Motor and Pump you have in your boat. There are two basic types of power Trim and Tilt Systems being used in the recreational Boating industry regardless of weather you have an Outboard or an I/O Sterndrive. Some of the older Power Tilt and Trim Systems used an Electric Tilt Motor in combination with a mechanical lifting device.

For example, Volvo Penta used a 12-Volt Power Tilt Motor turning a lifting screw on their older Stern Drives. On older OMC Stern Drives, an electric Motor turned a Worm Gear and incorporated a wet clutch pack to Tilt the drive unit as well as lock it into place. The Electric Hydraulic power Trim and Tilt System is more common. This type of system is used on Johnson and Evinrude Outboards, Mercruiser Stern Drives, Mercury Outboards and Volvo Penta Stern Drives.

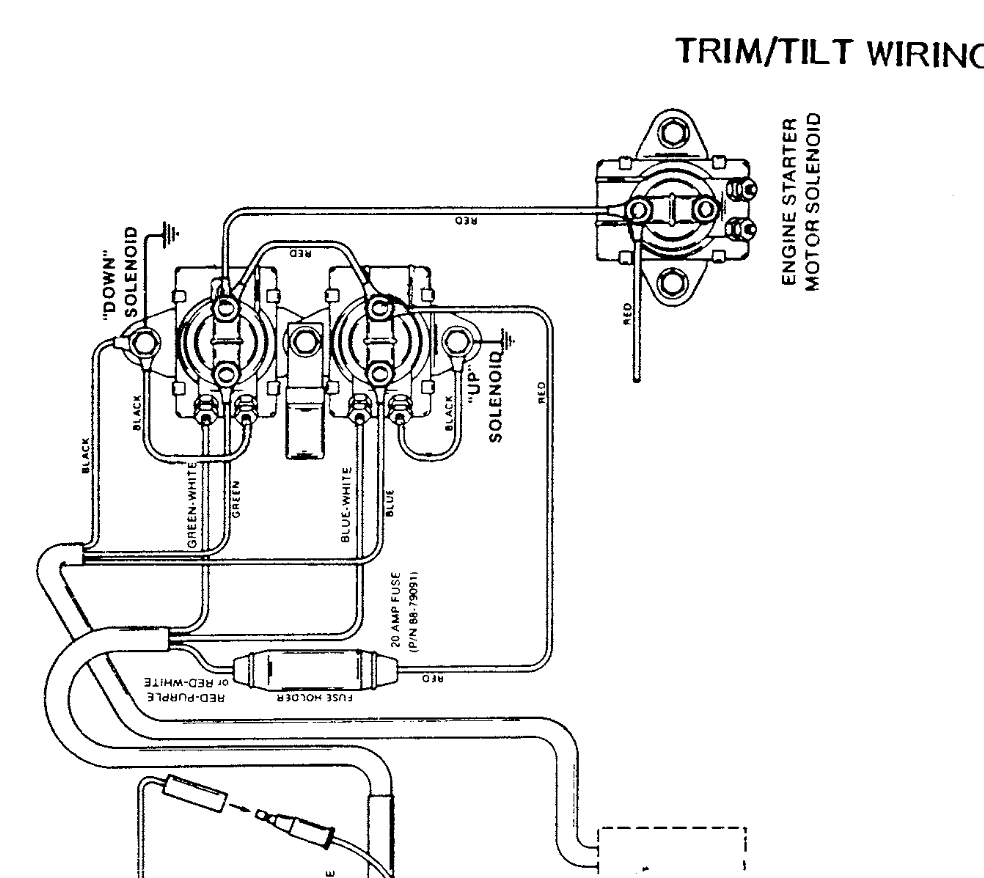

This system consists of two major components; the 12 volt electric Motor with a reservoir, and the Hydraulic Pump or Valve Body. Trouble Shooting Your Power Trim and Tilt System When experiencing problems with your power Trim and Tilt System, there are a few easy ways to diagnose just what the problem is. Generally come in two styles. All use a 12 volt D/C reversing Motor. Some Motors have a two wire connection and some Motors have a three wire connection. All power Trim and Tilt Motors come with one blue wire and one green wire. The three wire power Trim and Tilt Motors have an additional Black wire as well.

The Black wire works as a Ground on power Trim and Tilt Motors that don’t ground thru the case. When the blue wire is energized it raises the Motor or drive unit up. When the green wire is energized it lowers the drive unit down. When having a problem first you need to determine whether your problem is with the power Trim and Tilt Motor or the Hydraulic Pump Valve Body assembly.

If you attempt to raise the Motor or sterndrive to the up or down position and nothing happens, first check to make sure your Battery is charged and switched on if your boat is equipped with a Battery switch. If you hear a slight clicking noise you have power coming from the switch to the solenoid.

The next step is to go directly to the Motor and test it there. First, disconnect the power Trim and Tilt Motor. Using a jumper wire, apply 12 volts directly to the blue wire if your engine or drive unit is in the down position. It should raise up at this time.

If it is in the up position, apply power to the green wire reversing the Motor and lowering the unit. If the Motor runs, you may have a problem with a solenoid or lack of voltage coming from the power Trim and Tilt switch to the solenoid. If your power Trim Tilt Motor won’t run after this procedure it is time to replace it. Some replacement will come with a new wiring harness and relay kit to convert your old three wire power Trim and Tilt Motor to a new more powerful two wire Motor. Power Trim and Tilt Pump Problems Tilt and Trim Pump If your power Trim and Trim Motor is working fine but the engine or drive unit won’t stay Trimmed or bleeds down when in the up position, you most likely have a problem with the Hydraulic pump or Valve Body assembly.

9.9 Mercury Manual Trim Tilt

In that case it can be removed and rebuilt by a qualified repair facility. Replace the power unit and fill the reservoir with the correct Power Tilt and Trim Fluid per your owner’s manual. Generally, Transmission fluid is not recommended. It can be hard on some seals due to the high amount of detergents. Most power Trim and Tilt units will purge the air from the system just by running the engine or sterndrive up and down two or three times with the vent plug loose. Bottom line If the motor works in one direction there is nothing wrong with the motor.

The most common issue is a bad solenoid on a 3-wire motor or a bad relay on 2- wire motor. If the motor runs but won’t raise or lower the drive or outboard engine, check the fluid level first. If the level is full there is a problem with the pump. Makes a direct replacement for many models (in some cases your only option is to have the old pump rebuilt).

Hope this helps you repair your tilt/trim system so you can get out and enjoy your boat. If you need any parts, visit us at, or call toll free 1-800-998-9508. Article by: Michael Weller Go2marine.com Sales Manager Engine, Propulsion and Steering Systems Specialist. Steve February 20th, 2013 Thanks Mike, It turns out the tilt/trim relay had not been properly positioned recently when serviced so it fell onto the transmission linkage which then caused some trouble shifting to reverse.

That trouble was the relay impeding the linkage. That pulled one of the relay blocks to come almost completely unplugged from the relay and kinda crushed the side of one block on the relay. There was just enough contact for it to operate again. Will be replacing the relay box, and securing the relay where it belongs. Joe Bishop February 10th, 2013 Hi MikeI am prototyping a lifting device and would like to use a small light and compact 12 to 24 volt DC pump for power. What I really need to do is talk to an applications engineer at a company who makes a power unit similar to the one on my ’88 Chaparral 198XL w/ the 4.3 Mercruiser engine. Can you please steer me to the mfr or mfrs of these units so I can discuss my needs and develop a solution for my project.

Your help will be greatly appreciated My thanks, Joe Bishop. February 2nd, 2013 I have a 1993 Mercury, 3-cylinder, 2-stroke, 60hp outboard (model no. 0D186858, SN 1060412ND) with factory power tilt/trim. It has quit working at all. The motor ran at first, but quit after a time with no up/down. I tried to raise it manually by opening the manuel relief scew several turns, but it won,t raise manually with a lot of effort.

Other than a bad m otor, what else could be wrong with it? I have finally removed the whole tilt/trim unit from the outboard motor and am looking at what to do next. Are the ram seals (o-rings), etc. Hard to replace? Is rebuilding the pump below the electric motor hard to do?

Any guidence willl be appreciated such as parts I need to rebuild the ram and pump mechanism on the tilt/trim unit. Jim January 30th, 2013 Hi, the past 2 seasons I have been having trouble with my tilt motor. I can get the motor to go up and down but it takes about 5 minutes each way to get it to go up and down.

During this time, it makes a constant clicking as well as starting and stopping. Once I am on plane it is also difficult to trim my motor properly because it takes so long. It never has the Strong, whining type sound a strong motor has. It does have it occasionally after playing with the up and down controls on the trim switches. I bought a new aftermarket trim motor but haven’t installed it yet. A friend of mine thinks it may be the brushes?

Any suggestions are appreciated. Henry January 29th, 2013 I have a ’99 90hp Johnson that the foot is stuck in the up position.

Trim motor runs both in forward and reverse (up and down), reservoir is full, but foot doesn’t move a bit. Trim motor does not sound like it’s laboring at all. Boat is in the water at home dock and I can’t apply enough torque to the manual release to get it to move, afraid I might strip it. Nearest marina about 3 miles away, trying to avoid a tow if possible.

I can motor if I can drop the foot into the water. Any suggestions would be greatly appreciated! Leon gauthier October 21st, 2012 I have a 150 2001Johnson Outboard. As I was trimming out the motor the trim got stuck on up position and it would not stop running even after the motor was all the way. I played with the switch on the gear shift and the manuel on the motor but neither one of the would switch it off. I shook and looked for loose wires both nothing happened it kept running.l Finally after about a long 2 minutes it stopped. ‘we returned home I inspected everything and it now seems to be fine.

Question is what could have caused this and now that it is working what should I do to now to prevent it from happening again. Tom October 16th, 2012 I have 1987 Alpha 1. The out-drive will trim up on its own over time. This is more active as outside temps vary.

The pump works and will move the out-drive up and down but only to the limit point where the self lifting left it. It seems to form an artificial bottom trim point.

Mercury Trim & Tilt Leaking Around Dome

Under power in the water, the force will eventually push the outdrive to full down. At this point the trim works perfectly both up and down. Leave in storage and the rams begin to lift and reset a new bottom point. Doug Switzer September 20th, 2012 I have a 1988 four winns, the tilt worked right before we got to the dock, when we put it in the water to get ready to go I couldnt get the tilt to do anything. I could hear a clicking noise in what i thought was a relay and when I grabbed the relay I could feel it as it was clicking. I know it had juice to it because like I said it worked before so we could take the blocks out. Now it wont do anything, Im a first year boat owner so im not really sure what my next step is.

Do i change out the relay first or is it something else? Thanks, Regards. Doug Switzer. Al September 14th, 2012 Hi I have a 96 outboard E115GLEDR The back end of the boat went under water 2 years ago while not running. I thought it was worthless and let it sit.